Concrete is the most common construction material and is unconsolidated during its casting. It is therefore straightforward to think of installing permanent sensors inside it for maintenance purposes. The most widespread sensors embedded in concrete aim to monitor temperature and strain. They provide local information at the position of the sensors themselves.

In recent years new (piezoelectric, electromagnetic, electric) embedded sensors in concrete have been considered to provide quantitative information in volume so that sensors can therefore be installed without precise prior knowledge on damage location. Nonetheless, they still suffer from limitations: they require cables that need to be embedded with the sensors (often one cable per sensor) and when transient waves are at stake they use dedicated frequency range and thus cannot easily adapt to different resolution requirements.

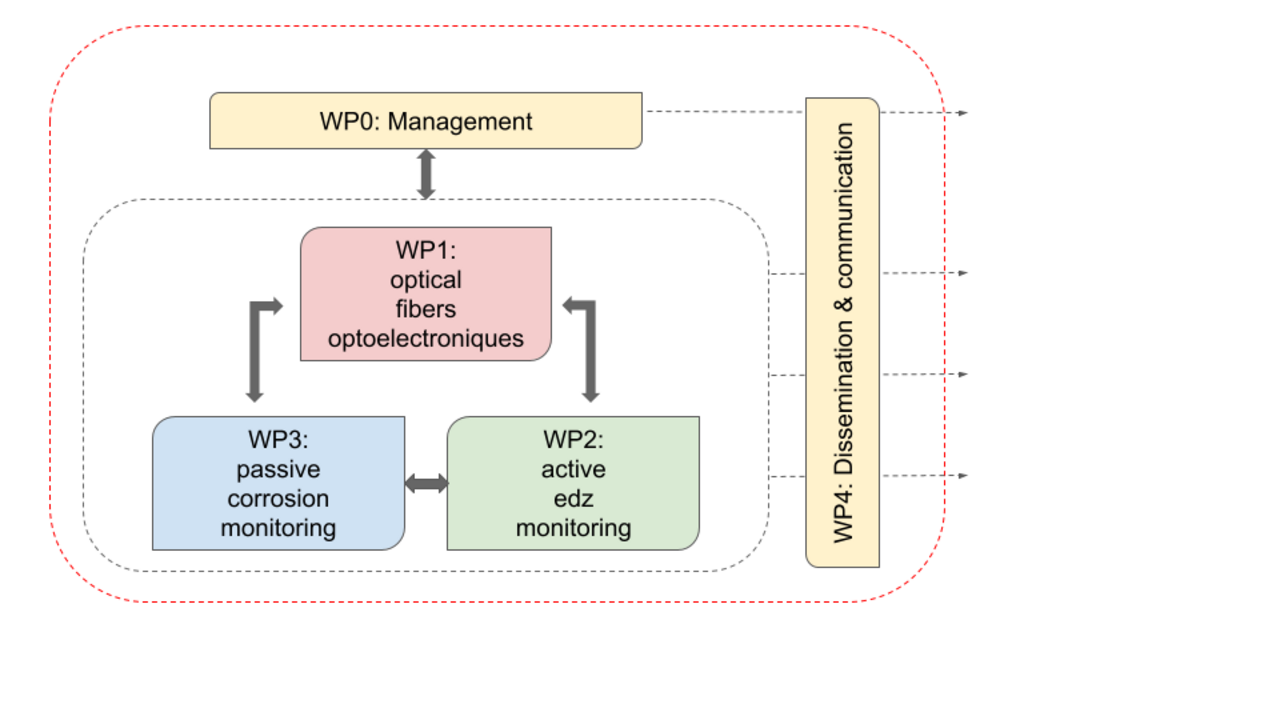

In this context, FO-US project aims to develop, characterize and validate a challenging new multichannel technology for ultrasonic measurements with embedded sensors, namely Fiber Bragg Grating (FBG) ultrasonic sensors on optical fibers. The advantages of an optical fiber for monitoring are numerous: its footprint and intrusiveness are very limited compared to other sensors, its durability makes it a good candidate for harsh conditions such as salty, high temperature or radioactive environment, and in addition, as a broadband transducer, it allows multiple-scale analysis.

FBG interrogation systems are currently limited in terms of number of sensors being simultaneously interrogated at ultrasonic frequencies on a single optical fiber. A major result of FO-US project will be the design, implementation and validation of an integrated 32 FBG sensors on a single optical fiber for the recording of ultrasonic signals at a sampling frequency above 5MHz with a technology compatible with industrial implementations and at a reasonable cost.

Technical barriers to be tackled are linked to the sensor and its optoelectronics and to the imaging algorithms and signal processing techniques to take into account the specificity of the optical fiber sensor constraints: a lower sensitivity, compared to classic embedded piezoelectric transducers, that furthermore depends on the wave direction and polarisation. The remediation of those technical barriers are partly application-related and therefore we have selected two generic challenging end-user cases in order to ensure that our results will be generalizable and demonstrated in the laboratory as well as in situ:

- Active recording of seismic signals with optical fibers will be investigated for the imaging and monitoring with body waves in a 3D medium of the Excavated Damage Zone around tunnels in claystone at Bure Underground Research Laboratory. A major result of the FO-US project will be a validated, and implemented in situ, time-lapse algorithm that integrates FBG characteristics for long term monitoring. Algorithms will be first tested on reduced scale models instrumented with FBGs at ultrasonic frequencies. In addition, the new ultrasonic FBG technology developed in FO-US project will be compared to optical fiber-based Distributed Acoustic System that faces resolution and sensitivity issues.

- Passive recording of guided waves propagation in concrete/steel/concrete pipes instrumented with optical fibers will be studied for the monitoring of corrosion of safety-classified pipes that transfer water for heat exchange in nuclear power plants operated by EDF. A major result of the FO-US project will be a methodology and the associated algorithms based on the noise resulting from the operation of the structure. They will take into account the multi-layered structure of the pipe, the characteristics of the noise, the optical fiber directional sensitivity and position to improve the maintenance of the pipes. The new ultrasonic FBG technology developed in FO-US project will be compared to existing embedded piezoelectric set-ups.